The spindle motor is heavy and the stepper motor is connected upside down, hence the stepper / axis joint screw is the one which will cope with all the weight. The complexity of the change is mainly due to: precision in the 3D print, installation of the lead screw and linear bearings.

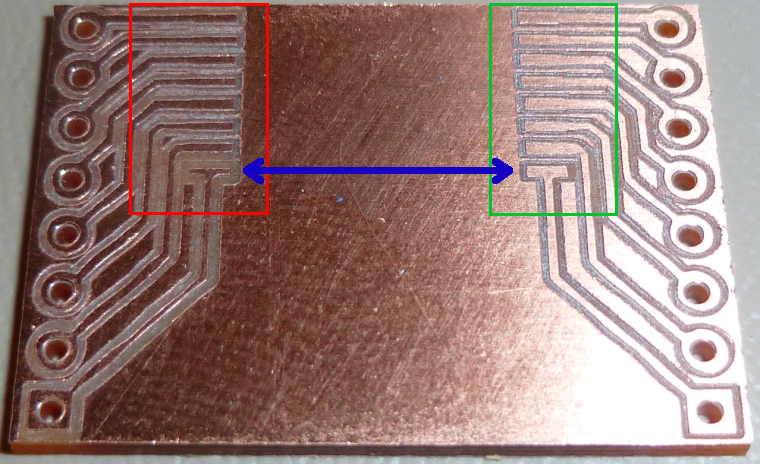

It is way less noisy, and more powerful nevertheless the change is particularly complex, and therefore I would suggest it only if the 775 is limiting your operations too much. It is way heavier, and its external diameter is bigger, therefore it does not fit in the original housing. The one I installed is a 100V, 500W air cooled spindle. By taking advantage of a low cost 3D printer and several parts, I changed the 775 spindle with a more powerful one. Moreover the auto homing feature can be turned on. Axis End stops: adding hardwired constraints to the CNC prevent unsafe displacement (in particular as far as X and Y axis is concerned).Simply connect two alligators clip to ground pin (any of the one GND), and to the PIN A5. Z-Probe : z-probe is a very useful addition to the CNC as it allows building an height map, which can cope with (low) build accuracy of the DIY CNC kit.

Most of them were inspired by the very useful webpage which is definitely worth reading : Mod list In order to get around those limitations, I modified the CNC and added several of the features which were not included out of the box (mostly to keep low the price tag). I may point out that although quite essential, its main board allows for quite some modding.

The 3018 CNC is simple, cheap and well, quite limited in terms of features. I recently purchased a 3018 CNC, so as to perform simple milling, cutting, and engraving operations.

0 kommentar(er)

0 kommentar(er)